Our company has adopted “Quality” as a philosophy in its R&D department, has determined research and development as a principle, and has made it a principle to solve our customers' unique and special color surface demands as soon as possible.

Quality product for Duston consists of 4 elements. These elements are;

The right chemical

The right machinery & equipment

The right staff

Education

If you want good service, please leave the quality to us.

ADHESION AND SCRATCH TEST

It is a method of testing the separation resistance of paint and coating from the substrate by cutting the paint and coating in the form of a lattice pattern to the substrate.

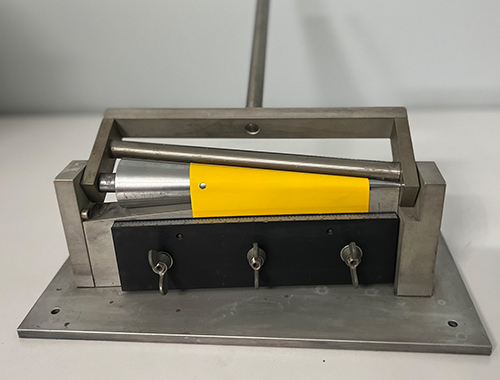

CONICAL BEND TEST

A painted panel is made by bending with a 5 mm conical mandrel. There should be no cracks when viewed with the naked eye

INDENTATION – CUPPING TEST

It is carried out in order to control the flexibility and adhesion of the paint. A steel sphere with a diameter of 20 mm is pushed on the unpainted surface of the test plate and the painted surface is deformed. It is also carried out in the form of determining the maximum indentation depth of the paint damaged during gradual cupping.

FILM THICKNESS MEASUREMENT TEST

There are two types of thickness gauges, Iron and Aluminum. For flat surfaces, there should be a thickness between 60-70 microns. On rough surfaces, the thickness should be 80-90 microns.

GLOSS MEASUREMENT TEST

The gloss measurement test is done with a glossmeter. Measurements are made at 20-60-85 degree angles. Rough paints are visually controlled.

HAZINESS MEASUREMENT TEST

It is measured at an angle of 20 degrees with a glossmeter.

COLOR MEASUREMENT TEST

They are devices used to create colors. In addition, color can be created by looking at any reference with the eye.

YELLOWING RESISTANCE TEST

The color change that occurs as a result of curing the powder paint at a higher temperature and time than the normal curing temperature and time is measured.

LIGHT BOX TEST

1.ARTIFICIAL DAYLIGHT

2.WHITE LIGHT

3.PURPLE LIGHT (UV)

4.FLAMENT LAMP

It provides the opportunity to see the color change of the painted panel in different lights.

ORANGE PEEL TEST

Evaluation is made according to the orange peel surfaces graded from 1 to 10 prepared by the Powder Coating Institute. 1 is the most orange surface, 10 is the best surface.

GEL DETERMINATION TEST

It determines the moisture rate of the Powder Coating. The required humidity should be in the range of 0.5-0.8%.

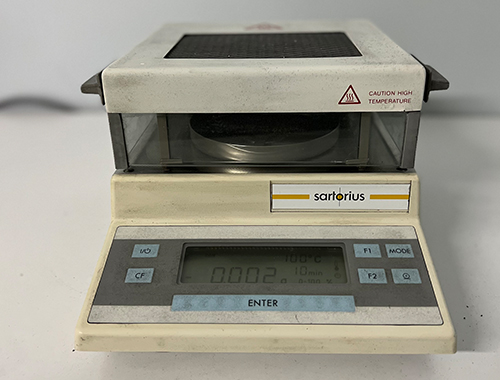

MOISTURE DETERMINATION TEST

It determines the moisture rate of the Powder Coating. The required humidity should be in the range of 0.5-0.8%.

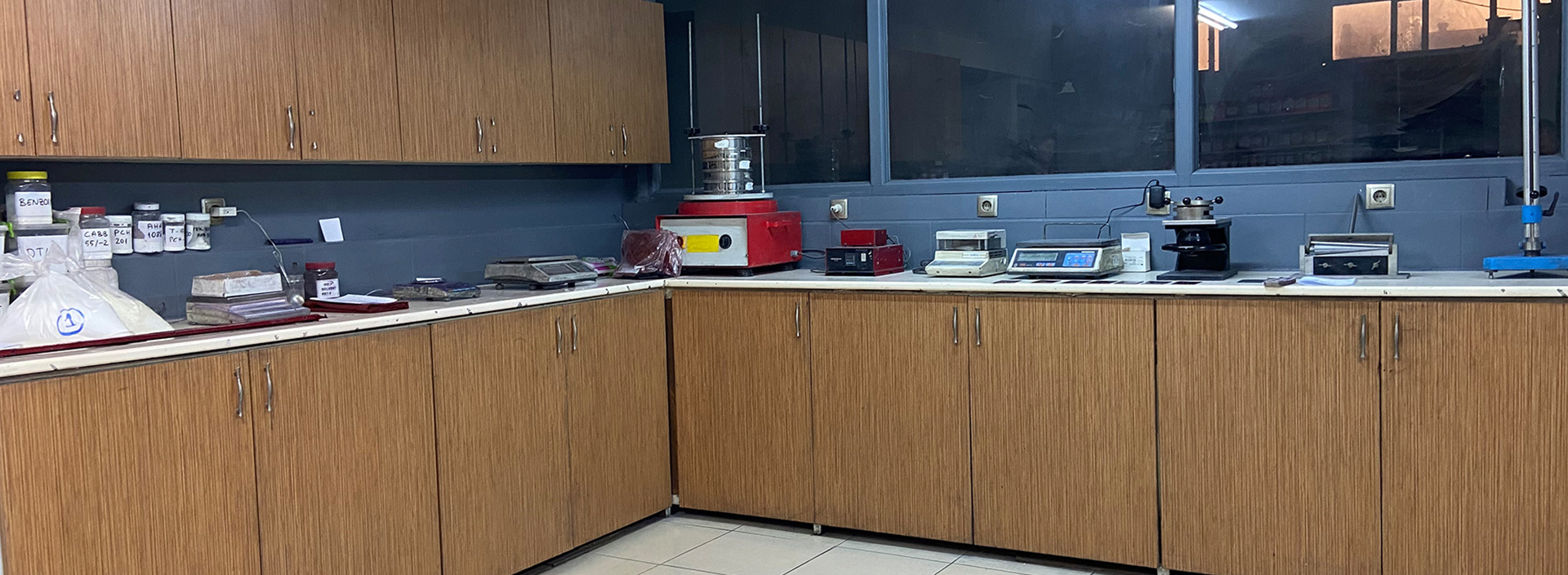

PARTICLE SIZE DISTRIBUTION TEST

The size range of the powder paint used in electrostatic painting should be 3-80 microns. For Tribo Paints, it should be 10-70 microns. Particle sizes of electrostatic powder paints can be measured by sieve analysis, optical methods (liquid or dry) and laser system.